Baldor-Dodge Conveyor Components

High performance and intelligent design delivering reliability throughout the world for over 100 years.

From underground mines to high in the mountains, Dodge customers expect outstanding performance from their conveyor pulleys.

Dodge delivers by stocking conveyor pulleys with Heavy Duty, Mine Duty and Mine Duty EXTRA constructions. With an extensive range of stock sizes and configurations, Dodge pulleys are available when you need them.

For the ultimate in performance and economy, Dodge offers Engineered conveyor pulleys. Dodge engineers utilize FEA models and state-of-the-art technologies to design conveyor pulleys assemblies of the highest quality.

With unmatched conveyor pulley engineering and manufacturing capabilities, Dodge has the knowledge and expertise to deliver reliability worldwide.

Engineered Pully Product Features

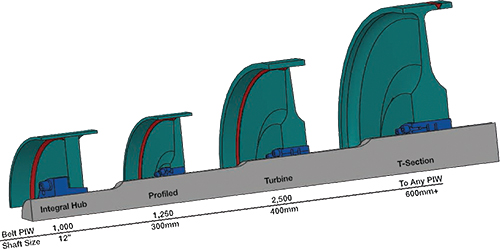

- Integral hub, profiled, turbine and T-section end disc designs

- Vulcanized lagging

- Standard SBR, fire and oil resistant Neoprene, or abrasion resistant D-LAG

- High-traction ceramic (available cold bonded or vulcanized)

- HE, XT or Bikon shaft locking devices

- Standard 1045 or high strength 4140 shaft material

- Static and dynamic balancing

- Available stainless steel construction for non-magnetic applications

- Serialized nameplates

- 2 year extended warranty

Manufacturing Capabilities

- High-strength submerged arc welds

- Thermal stress relieving

- CNC machining of shaft and pulley

- Expert assembly of pulley, shaft, bearings, coupling and backstop

Quality Certifications

- ISO 9001:2008

- AWS and ASME certified welding procedures and welders

- Submerged arc welding

- Gas metal arc welding

- Gas tungsten arc welding

- ASNT NDE certified inspection program

- Ultrasonic, magnetic particle, dye penetrant testing and visual inspection

- Material certifications on all materials

Engineered pulley end disc designs

|

|